info@shxvalve.com

info@shxvalve.com info@shxvalve.com

info@shxvalve.comTel:+86-17717520739

Email:info@shxvalve.com

Address: NO.720, Suide Road, Jiading District,Shanghai, China.

2022-12-02

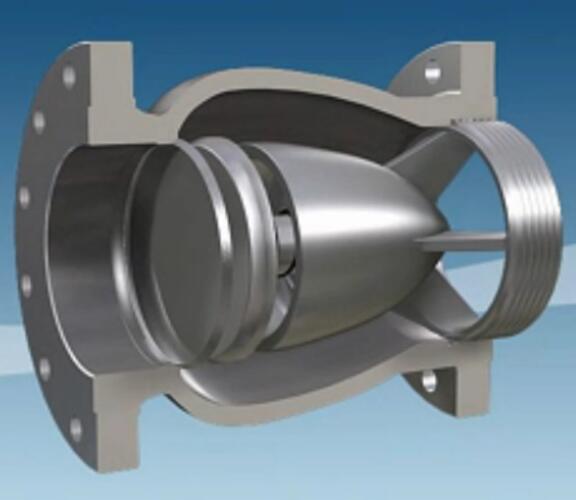

An axial flow check valve is a kind of silent check valve. The axial flow check valve is driven by the medium itself and automatically opens and closes the valve disc. Generally, it is used to prevent the backflow of fluid or gases. A flow check valve can be called a one-way valve, non-return valve, backflow valve, backstop valve, and back pressure valve. An axial flow check valve has been a popular industrial valve since 2008. This valve has the function of the general check valve and is designed with a shock-absorbing spring, combined metal seat, and soft seat structure, which is easy for end-user maintenance on site.

The axial flow check valve adopts a particular sealing structure. Whether the downstream pressure is high or low, the valve is permanently closed tightly and has excellent shutoff performance. It overcomes the disadvantage of the lack of shutoff performance of the general check valve at low back pressure. The axial flow check valve that has a unique axial flow shuttle structure. It has the advantages of small flow resistance, significant flow coefficient, compact design, etc. It is the best valve for oil and gas gathering and transmission pipeline systems, especially for the outlet of oil transmission pumps.

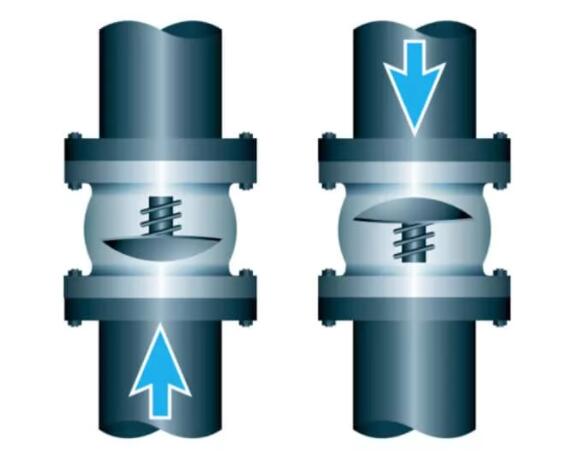

The axial flow check valve also is a kind of non-slam or silent check valve, which is designed as a self-actualizing device and responds in a piping system to either pressure or flow changes. The main purpose of a non-slam axial flow check valve is to restrict or shut off the flow in the reverse flow direction. The important thing is that the normal position of a nozzle check valve is a valve close position with silent and non-slam closing action.

The primary function of a axial flow check valve is to prevent the water hammer and closing rapidly without slamming. When flow is reversed in a pipeline, it will cause hydraulic shock waves to pass through the valve, it also called the water hammer phenomenon. The water hammer can cause damage to the equipment in the pipeline, so we must prevent this phenomenon. So selecting the right axial flow check valve is the best way to prevent damage from occurring and causing serious issues at the site when the valve is in a fully closed position during reverse flowing through.

An axial flow check valve is a kind of non-slam check valve, when the valve closes it won’t have a slamming phenomenon, and there are no excess pressure spikes are generated. Aixa flow check valve is simply designed with spring-loaded and a single low-mass valve disc that enables fast response, and dynamic reaction to the reduction in flow. The working principle is easy to understand, when the disc of the axial flow check valve is opening, the force of the single disc and spring is balanced that resulting in uniform flow.

When the pressure difference between the upstream and downstream of the valve exceeds the crack pressure of the spring, the obturator moves and allows flow. With the venturi design that the flow area of the valve steadily decreases to the seat diameter, and the reduced flow area increases the dynamic pressure and reduces the static pressure, allowing the valve to open fully and quickly. The spring is selected to allow the disc to open fully and stabilize on its backstop under normal flow conditions.When the flow rate is significantly reduced, the spring responds in advance to the force of the reduced flow.

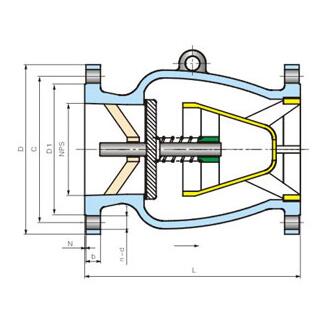

The components of the piping system include pumps, valves, compressors, elbows, bends, and reducers, and it will cause turbulence in the flow stream. In case to improve the service time of an axial flow check valve, you need to install it in accordance with best industrial practice, which means we need to keep enough distance from the turbulence source that makes the valve is in fully developed flow. The following figures are the best practice installation for nozzle non-slam axial flow check valves.