info@shxvalve.com

info@shxvalve.com info@shxvalve.com

info@shxvalve.comTel:+86-17717520739

Email:info@shxvalve.com

Address: NO.720, Suide Road, Jiading District,Shanghai, China.

2022-09-22

In a fluid system pulsating high pressure is a cause of maximum damages occurs. Also, if the pressure is very high in comparison to what is required for a system, it will cause the wastage of fluid (in domestic water system), leakages in the long run as the system is designed for handling lower pressure, and it can also lead to a pipe burst or system breakdown. All this will ultimately reduce the efficiency of the system and will contribute to the higher operating cost for a business.

This reduction in efficiency of a fluid system can be controlled by a constant and reduced pressure supply in a system. This can be achieved by using an Automatic pressure regulator or a Pressure Regulating Valve.

The basic function of a Pressure regulating valve in a fluid system is to convert a pulsating & high inlet pressure to a constant & reduced (or pre-set) pressure.

If there is a requirement for pressure reduction between two components of a process, a pressure regulating valve will open. These valves can lower liquid or gas pressure to a predetermined level.

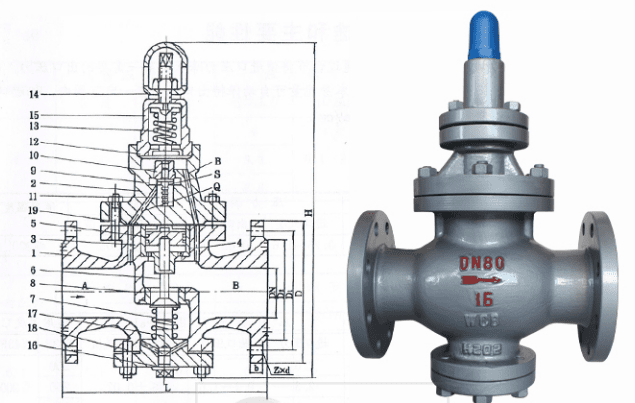

The pressure reducing valve is a hydraulically powered, diaphragm actuated control valve that decreases greater upstream pressure to lower constant downstream pressure of variable demand or varying upstream pressure. It is designed to resist even the harshest conditions. Essentially, the valve maintains a constant downstream pressure regardless of flow.

The operation of pressure reducing valve is dependent on the balance of fluid pressures acting over and under the piston, as well as the spring force. If the low-pressure fluid and spring force are more than the high-pressure supply, the piston will close the valve. When the low-pressure fluid force is reduced, the new fluid pressure and spring force are less than the high-pressure supply fluid, causing the piston to open the valve. The valve will frequently open and close in order to maintain the pressure under control. The valve’s outlet pressure may be adjusted by changing the spring to a stronger or weaker one as needed. In certain situations, the spring force is adjusted via an adjustable screw. Some reducing valves employ several pistons as well as diaphragms to improve performance.

Pressure reduction valves are categorized into two main categories based on the mechanism that controls the valve opening:

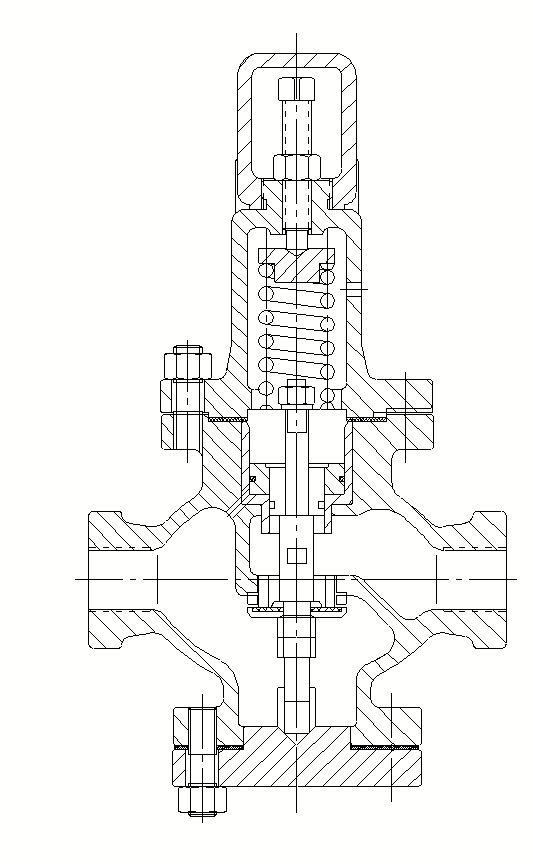

Direct-acting Pressure Reducing Valve: Direct-acting pressure reduction valves are excellent for lower pressures that do not require precise pressure control. They are made in a small size, are cheaper, and are easy to set up. In comparison to their pilot-operated counterparts, they often have higher fluctuation from the set pressure. This is the most basic form of a pressure-reducing valve, with either a flat diaphragm or a bellows. Because it is self-contained, it does not require an external sensing line downstream to function.

The amount of valve opening in the direct acting pressure reduction valve is regulated directly by the movement of the adjustment spring. When the spring is compressed with the help of an adjusting screw, it generates an opening force on the valve, causing the flow to rise. As pressure develops downstream, equalization is done by transferring the downstream pressure to the underneath of the adjustment spring, where its upward force counterbalances the compression of the spring. The spring compressive force that opens the valve is restricted to provide for adequate spring sensitivity to equalize with variations in downstream pressure. As a result, pressure is simply controlled by a valve opening, where excessive flow rates might result in pressure drop.

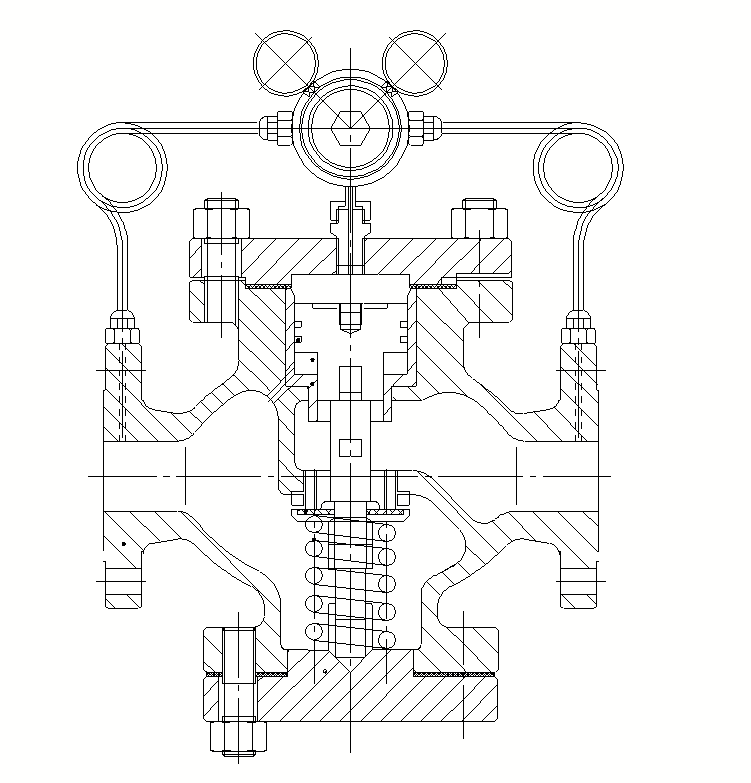

Pilot operated Pressure Reducing Valve: These valves are often utilized for higher loads that need precise pressure control. When compared to direct-acting models, they give a quicker reaction to load fluctuation and are suited for a larger range of flow rates. They are larger and more expensive.

A pilot valve is used in pilot-operated pressure reducing valves to load a piston or diaphragm, increasing the downward force required to open a larger main valve. In the same way that a direct-acting valve functions, the pilot valve’s opening, and shutting are regulated by the balance of force between the adjustment spring and the secondary pressure. In a pilot-operated valve, however, the opening and shutting of the pilot valve are done on purpose to supply pressure to the main valve piston or diaphragm. This pilot flow pressure generates a downward push, which is magnified by the area of the piston or diaphragm, allowing for the opening of a much bigger main valve, allowing for extremely high flow rates.

A minor change in the pilot valve opening can result in a substantial change in flow and downstream pressure via the main valve because the downward force is magnified by the employment of a piston or diaphragm. As a result, the adjustment spring force on the pilot only needs to be changed a little to achieve rapid reaction over a wide range of steam flow rates. The major benefits of this type of valve over direct-acting valves are quick reaction and precise delivered pressure control.

Pilot operated pressure reducing valves are further divided into two types:

These valves are used in various sectors such as water services, Air & Gas Services, Hydraulic systems, Steam services, Fuel oil systems in IC engines and Boilers, etc.

When choosing a pressure reducing valve, make sure you obtain a product that is of good quality, is cost-effective and will last for many years.

Flow (Q) = Cv × (square root Pressure Differential)

While doing the maintenance on these valves, consider the following points.